WETT names Marshall Byle as Honorary Member

WETT is pleased to announce that Marshall Byle has been named an honorary member of the organization. Honorary Membership is bestowed by unanimous vote of the Board of Directors upon an individual who has demonstrated exceptional commitment to the organization and/or to the WETT Inc. professional training system.

About 45 years ago I built my first wood stove. As Vanessa Percival pointed out, it was the wild west back then. Oil embargoes were taking place, electrical prices were high, and people were installing wood-burning stoves with no certification and sketchy installation rules, even in the building codes. Small-town fire departments were called to deal with chimney fires, often, several per week.

I was serving a boilermaker apprenticeship at the Bruce Nuclear Development but decided to start a part-time chimney sweep business to help pay my mortgage, which renewed at 20% back then. (Sound familiar?) Eventually, I became a part-time nuclear worker and full-time solid-fuel technician, operating a full-service retail store.

Opportunities arose to be involved with the Ontario Chimney Sweeps Association, the Canadian Standards to develop training requirements for sweeps and solid-fuel technicians and, later, B365. When WETT got started, you couldn’t keep me out of it. Taking the first train-the-trainer courses with the best people across Canada was a tremendous experience. Jan Herald and I often delivered training together and later teamed up to upgrade some of the courses.

Over the years I had the opportunity to deliver WETT training all over Ontario and delivered the first courses in Manitoba and Saskatchewan.

I don’t think I ever delivered a course without learning something myself. What a privilege.

Marshall is now retired and lives in a woodlot, still burning wood. He also continues to write a monthly column called “Rooftops” for the Bruce County Marketplace magazine. Has been writing this column for over 30 years.

Marshall Byle

WETT President, 1998/1999, 2000/2001

Selkirk Training Bursary: Congratulations to Our 2023 Bursary Winner

Selkirk Canada Inc. and WETT would like to congratulate Mitchell Somerville, the 2023 winner of the Selkirk Training Bursary.

Mitchell works as a sales associate for The Fireplace Centre, in Kamloops, BC. Mitchell's roles include sales and installations. He also attends trainings and studies installation manuals. Mitchell feels that becoming WETT certified is an important step in his development as a hearth professional.

During his time at The Fireplace Centre, Mitchell has proven himself to be irreplaceable. His positive attitude helps make the shop a happy and friendly place to do business.

The purpose of this bursary is to provide financial assistance to a person seeking WETT certification as an installer, system advisor or sweep following the WETT paths to certification. This bursary will cover the course fees for one individual per year seeking WETT certification.

Submission deadline September 30.

Congratulations to our 2023 Elizabeth Mason Academic Achievement Award Winner

In memory of Elizabeth Mason, who passed away in 2008, WETT created the Elizabeth Mason Academic Achievement Award.

Elizabeth was a long-standing WETT member committed to advancing the goals of the organization.

WETT is pleased to announce that Waldemar Beitler — from Ste. Anne, MB — is the 2023 award winner.

Wood Stoves Installed in Residential Garages / WETT Inspections™

By Ian Myers

Having the right and ability in Canada, under CSA B365 Installation code for solid-fuel-burning appliances and equipment, to install a wood stove into a residential garage may not be much of a concern for urban communities, but for many rural areas it is an important option.

The following are two, notable, additional requirements, while installing in a residential garage, that are not required when installing within a residential dwelling.

The applicable clause: 4.3 Hazardous Locations

An appliance shall not be installed in a location where a corrosive atmosphere, flammable gas or vapour, combustible dust, combustible fibres might be present. It may be installed in a

(a) storage or residential garage, provided that the appliance is mounted in such a manner that any component representing a source of ignition, such as a blower or bottom of the firebox, is at least 450 mm (18'') above the floor level and protected against physical damage.

Naturally, should a significant amount of flammable liquid be spilled within the garage (such fumes being heavier than air) having the air intake of the wood stove at least 18'' above the floor would help to prevent fumes from immediately being drawn into the fire box of the wood stove causing an explosion or fire. The additional “protection from physical damage” (such as a pole or curb in front of the appliance) should the stove be installed, in-line, such that it could be struck by a moving vehicle — would further contribute to the over-all safety of the installation.

These are all “well and good,” positive installation instructions. However, it does contain a contradiction, that from my experience results in a percentage of WETT inspectors declaring while inspecting that wood stoves in garages are “non-compliant,” beginning with the title of such installations being 'Hazardous Locations' and the introductory sentence declaring a hazardous location to be defined as a place where “flammable gas or vapour might be present.”

I am on the CSA B365 Technical Committee and I brought this topic up at our last meeting and requested that this wording be changed.

My rationale for the change, essentially is that it is a contradiction, as evidenced by what is not an unreasonable reading of the current Code. If an installation location was dangerous then CSA B365 would not be advising how to proceed.

Further, as installers and inspectors, using the Code — we do not assume responsibility for potential use or operation of that which has been installed or inspected, we do not inspect for “potentials,” if we did, then no appliance of any type would be installed anywhere.

I also said, that I understand and respect the message behind the current composition, but that education regarding usage, including the space where an appliance is located should best occur by other means. For example: the new WETT inspection forms have a page regarding Fire Codes, for educational purposes, plus there is an inspection point referring to the Hazardous Locations clause; this would be an excellent place to educate the public, with an additional, specific note for the user of the appliance which has just been installed or inspected, all the more reason for insurance companies to request a current WETT Inspection™ for wood-burning systems.

So, my suggestion was a simple one, that the word be changed from “might” be present, to – “is” present. By all means, while inspecting, if fumes or large amounts of combustible dust are present it should be noted as “non-compliant” in the Hazardous Locations category.

It is important to note, that gas and solvent containers being present in a garage are not hazardous. The design of such containers are also governed by Codes, up to and including how many units can be stored at one location. The analysis of such factors is outside of the expertise and definition of a WETT Inspection™.

It is important to clarify and amend the wording of our Codes in response to their “real-world” use. We certainly do not want them to be applied in an unintended way.

It is important that rural areas continue to have the option of a solid fuel burning appliance in their garage and our industry should protect that right.

WETT names Vanessa Percival as Honorary Member

WETT is pleased to announce that Vanessa Percival has been named an honorary member of the organization. Honorary Membership is bestowed by unanimous vote of the Board of Directors upon an individual who has demonstrated exceptional commitment to the organization and/or to the WETT Inc. professional training system.

At 18 years old I used a wood stove for the first time, and I was hooked! I loved everything about it… the connection to the natural world, freedom from corporate fuel supply, and most of all the warmth.

I started working in a woodstove store in my early twenties, and boy, was it the Wild West out there in terms of installation guidelines, rules or codes! When I opened Embers in Perth, Ontario I registered for WETT courses right away. I understood the value of the education offered by the WETT program and was not disappointed in the information, trainer or course materials. Meeting other people that were on the same journey and sharing stories and laughs with these folks was precious.

When John Gulland asked if I would consider being on the WETT board, I gladly agreed. Having worked with HPBAC and WETT I saw the value they had to my business and was pleased to be involved with the board. We did some great work, a lot of energy went into coaxing the government that EPA emission standards needed to implemented in Canada. The Burn it Smart program took us all over Ontario, into Quebec and even into the US connecting with other retailers, installers, distributors and homeowners during the delivery of these very hands on Burn it Smart courses. There was always the important, ongoing work of course updates and development. All in all, working with WETT was very rewarding and I’m so glad I had the opportunity to work with a truly wonderful group of people, achieving some remarkable goals.

I am retired now, and gladly heating my house with a Jotul TL50, which I split and pile the wood for each year. Still loving the connection to nature, and teaching my Grandkids to do the same.

Vanessa Percival

WETT President, 2002-2005

Happy Holidays from WETT

The team at WETT would like to extend our best wishes to you all for a safe and peaceful holiday season. We hope you are able to enjoy the festivities with family and friends. Looking forward to what the new year will bring!

Holiday Office Hours

The WETT Board of Directors and national office will be unavailable from 5 p.m. ET on Friday, December 22, 2023 to Monday, January 1, 2024 inclusive. We will be back at 9 a.m. ET on January 2 and will make every effort to respond to all inquiries within the first 48 hours upon our return.

See you all in the new year!

Updates to B365-17

Here is the most recent update to the CSA B365-17. Click here to download it, and make sure to add it to your hardcopy.

Fire Prevention Week is October 8-14, 2023

This coming weekend is Thanksgiving. While enjoying your wood-burning fire, remember to take precautions. In honour of Fire Prevention Week, we provide you with the following article. As always, stay safe.

This article was provided as a public information piece by the WETT Communications Committee for members to share. We recommend that you share it with your networks/client base as a marketing tool for your business.

Chimney Fire Facts

As you snuggle in front of a cozy fire or bask in the warmth of your wood stove, you are taking part in a ritual of comfort and enjoyment handed down through the centuries. The last thing you are likely to be thinking about is the condition of your chimney. However, if you don't give some thought to it before you light those winter fires, your enjoyment may be very short-lived. Why? Dirty chimneys can cause chimney fires, which damage structures, destroy homes and injure or kill people.

Fireplaces and wood stoves are designed to safely contain wood-fuelled fires, while providing heat for a home. The chimneys that serve them have the job of expelling the by-products of combustion — the substances given off when wood burns.

As these substances exit the fireplace or wood stove, and flow up into the relatively cooler chimney, condensation occurs. The resulting residue that sticks to the inner walls of the chimney is called creosote. Creosote is black or brown in appearance. It can be crusty and flaky; tar-like, drippy and sticky; or shiny and hardened. Often, all forms will occur in one chimney system.

Whatever form it takes, creosote is highly combustible. If it builds up in sufficient quantities — and catches fire inside the chimney flue — the result will be a chimney fire. Although any amount of creosote can burn, sweeps are concerned when creosote builds up in sufficient quantities to sustain a long, hot, destructive chimney fire.

Certain conditions encourage the build-up of creosote: restricted air supply, unseasoned wood and cooler-than- normal chimney temperatures are all factors that can accelerate the build-up of creosote on chimney flue walls.

Air supply

The air supply on fireplaces may be restricted by closed glass doors or by failure to open the damper wide enough to move heated smoke up the chimney rapidly (the longer the smoke’s “residence time” in the flue, the more likely is it that creosote will form). A wood stove’s air supply can be limited by closing down the stove damper or air inlets too soon and too much, and by improperly using the stovepipe damper to restrict air movement.

Burning unseasoned firewood

Because so much energy is used initially just to drive off the water trapped in the cells of the logs, burning green wood keeps the resulting smoke cooler as it moves through the system than if dried, seasoned wood is used.

Cool flue temperatures

In the case of wood stoves, fully-packed loads of wood (that give large cool fires and eight- or 10-hour burn times) contribute to creosote build-up. Condensation of the unburned by-products of combustion also occurs more rapidly in an exterior chimney, for example, than in a chimney that runs through the centre of a house and exposes only the upper reaches of the flue to the elements.

Failing to maintain your woodstove or fireplace properly can lead to a chimney fire. Chimney fires occur when creosote deposits on the inner walls of the chimney ignite. A fire hazard exists if 1/4 inch of creosote (or more) coats the inner walls of the chimney.

Chimney fires can burn explosively — noisy and dramatic enough to be detected by neighbours or passers-by. Flames or dense smoke may shoot from the top of the chimney. Homeowners report being startled by a low rumbling sound that reminds them of a freight train or a low flying airplane. However, those are only the chimney fires you know about. Slow-burning chimney fires don’t get enough air or have enough fuel to be as dramatic or visible. But the temperatures they reach are very high and can cause as much damage to the chimney structure — and nearby combustible parts of the house — as their more spectacular cousins. With proper chimney system care, chimney fires are entirely preventable.

WAYS TO KEEP THE FIRE YOU WANT... FROM STARTING ONE YOU DON'T!

Chimney fires may even occur in clean, intact, properly installed chimneys. Have a WETT-certified chimney sweep clean and inspect your appliance at least once a year. More frequent cleanings may be required, based on the type of wood burned, the type of appliance and the frequency of use. In general, an older, uncertified wood stove, or any appliance that is used frequently, will require more than one cleaning per year.

Make sure a WETT-certified chimney sweep inspects your solid-fuel-venting system annually, and cleans and repairs it whenever needed.

Chemical cleaners and/or log products should not be used for maintenance in a wood-burning appliance. Do not depend on them to clean your chimney. A chimney requires professional sweeping on a regular basis; regular chimney inspections are always recommended. The Creosote Sweeping Log (CSL) will not tell you if your chimney is blocked or has any kind of structural damage. The Creosote Sweeping Log does not take the place of inspection and professional cleaning.

Your sweep may have other maintenance recommendations depending on how you use your fireplace or stove. WETT recommends that you call on certified chimney sweeps, since they are regularly tested on their understanding of the complexities of chimney and venting systems.

Chimney fires don’t have to happen. Here are some ways to avoid them:

Use seasoned woods only (dryness is more important than hard wood versus soft wood considerations)

Build smaller, hotter fires that burn more completely and produce less smoke

Never burn cardboard boxes, wrapping paper, trash or Christmas trees; these can spark a chimney fire

Install stovepipe thermometers to help monitor flue temperatures where wood stoves are in use, so you can adjust burning practices as needed

Have the chimney inspected and cleaned on a regular basis

Detection

The first indication of a chimney fire is usually the noise — a roaring sound that grows louder as the fire’s intensity increases. Clouds of black smoke and sparks will be seen exiting the top of the chimney; in severe fires, flames can extend several feet about the chimney.

Action

In case of a chimney fire, follow these steps:

Call the fire department immediately.

If able to, close the appliance’s dampers and/or the primary air inlet controls, limiting the fire’s air supply and reducing its intensity. If there is a barometric damper in the chimney connector, plug or close the opening in the barometric damper.

Alert and assist everyone in the house to evacuate, including you.

Closely monitor all combustible surfaces near the chimney. During severe chimney fires, these surfaces can become hot enough to ignite.

After a chimney fire, have the chimney inspected by a WETT-certified chimney technician/sweep. Contact your insurance carrier.

DO NOT USE THE CHIMNEY UNTIL IT HAS BEEN INSPECTED by a WETT-certified technician/sweep. The excessive heat produced by a chimney fire can crack chimney walls, damage chimney liners, and damage some types of factory- built chimneys. If not repaired, these damages create a greater possibility for any subsequent chimney fire to spread beyond the confines of the flue to the house.

Signs that You've Had a Chimney Fire

Since chimney fires can occur without anyone being aware of them ... and since damage from such fires can endanger a home and its occupants, how do you tell if you've experienced a chimney fire?

Here are the signs a professional chimney sweep looks for:

“puffy” creosote, with rainbow-coloured streaks, that has expanded beyond creosote’s normal form

warped metal of the damper, metal smoke chamber, connector pipe or factory-built metal chimney

cracked or collapsed flue tiles, or tiles with large chunks missing

discoloured and distorted rain cap

creosote flakes and pieces found on the roof or ground

roofing material damaged from hot creosote

cracks in exterior masonry

evidence of smoke escaping through mortar joints of masonry or tile liners

If you think a chimney fire has occurred, call a WETT-certified technician/chimney sweep for a professional evaluation. If your suspicions are confirmed, a certified sweep will be able to make recommendations about how to bring the system back into compliance with safety standards. Depending on the situation, you might need a few flue tiles replaced, a relining system installed or an entire chimney rebuilt. Each situation is unique and will dictate its own solution.

Reminder: WETT Resources for Members

Valued member,

As a follow up to our previous communication on the launch of new resources for members, we are pleased to provide some further updates.

The organization has secured a trademark for the title “WETT Inspections™.” This provides us with an opportunity to further reinforce the quality and integrity of inspections undertaken by our qualified members. In order to ensure consistency, WETT has worked to develop the following resources to compliment the use of the term “WETT Inspection™.”

Standards of Practice for Inspections

SITE® Table

WETT Inspection Forms

SITE® Inspection Course

In keeping with our Mission Statement:

_______________________________________

“To foster and promote among certificate holders the highest level of professional conduct in the delivery of services to the public.”

Standard of Practice (SOP) for Inspections: This provides our membership with best practices in providing inspections to the general public and ensures there is consistency across the board with how our members engage with clients.

There is an element of potential liability, so a thorough and consistent method of work is required — do your due diligence, as both a credit to you and your professionalism as well as to the customer who hired you. Ensure the homeowner is fully aware of the extent of your contracted WETT Inspection® services. You can use the Consumer Inspection Brochure, found in the Documents section of the members’ section of the WETT Inc. website, to help you.

WETT-certified professionals are all bound — both ethically and by code requirements — to adhere to a high standard of professionalism. This includes advocating on behalf of:

the manufacturer of an appliance;

the governing bodies & authorities having jurisdiction that their business practices are aligned with and;

the homeowner who has selected a WETT-certified professional to review the installation of that appliance.

These standards of practice are the first step, with standards currently in development for installers and chimney sweeps.

“To encourage and promote the safe and efficient use of wood energy through the distribution of public information materials through the collaboration with government agencies and related industries.”

SITE® Table: To further enhance our communication with members and the general public, WETT has also re-developed the SITE® Levels of Inspection table that has stood as a guide for inspections for many years. Through feedback from both members and the public, we determined that further clarity to this table was required. This will stand to further enhance open communication between members and the public. The team has since created two versions:

A SITE® table for members: provides some clarity on what the minimum expectations are when inspecting, and what some key indicators are for deciding to move to a more comprehensive approach.

A SITE® table for the general public: provides a view to what is included in an inspection, with some key indicators that may require a WETT-certified professional to recommend further exploration. This table was developed with careful consideration to technical terms that the general public may not fully comprehend.

These tables say the same thing, but the language is tailored to each audience.

The WETT Reference Manual states “The inspection of a solid-fuel-fired heating system is a demanding and sensitive job.” Managing a homeowner’s expectations of what will be provided to them is key; educating the general public about the types of inspection & determining the correct type of inspection required for their purpose is important.

“To promote the interests and activities of the members of the organization in a reasonable and legal manner.”

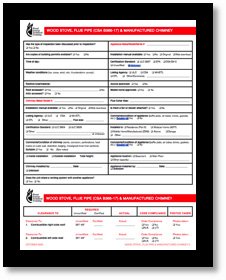

Recommended Inspection Forms: These forms have been updated and are available in the Documents section of the members’ section of the WETT Inc. website. These forms are strongly recommended for member use and stand to ensure consistency in the service that our members provide to the public.

The forms have been designed to guide you through a thorough inspection, complete with references to codes and recommendations for photos and documentation.

Ensure you fill out as much information in the forms as possible. Have the manufacturer’s certified installation instructions available during your inspection to help you determine & document correct clearances. Take lots of pictures, as these will assist in your reporting practices. Ensure all safety & code requirements have been met (carbon monoxide detectors are required in all locations). Know your local building and fire code requirements as well.

SITE® Inspection Course: The new SITE® inspection course has been developed to train our members — and those on the path to certification — on the use of all the tools mentioned above. The comprehensive, two-day course (with online pre-course module) has been mandated as the next continuing education course for all existing members, and has replaced the SITE® Basic Inspection and SITE® Comprehensive Inspection courses.

We are sure you will benefit from the use of these valuable resources, made available to you as WETT-certified members, to further enhance the value of the title “WETT Inspections™.”

All of these tools and initiatives have been developed to work as a unit with one goal in mind; bridging the communication gap between WETT-certified professionals and those we service. We are confident that you will find them valuable resources and a benefit of WETT membership.

WETT is looking to fill the position of Education Coordinator

As a member in good standing, we wanted to provide you with the opportunity to respond to the attached request for proposal (RFP).

This RFP solicits proposals from qualified individuals in providing educational development services that support WETT Inc with its course curriculum, material review and instructor development.

Reporting to the Executive Director, and in conjunction with WETT experts, the following list briefly outlines the scope of work to be provided:

Content management

Course administration

Review/update course materials

Course development and review

Recruit and orient instructors and assist with skills development.

Approximately 700 hours per year (15 hours per week).

A letter/email expressing interest must be received no later than Friday, July 31, 2023. Your full proposal must be submitted no later than Friday, August 11, 2023 by email to manager@wettinc.ca, info@wettinc.ca & web@wettinc.ca.

Click here to view the RFP.

John Gulland Accepts the WETT Award of Excellence

The WETT Award of Excellence recognizes an individual who has made significant contributions to advancing the objectives of WETT Inc.

Our 2023 recipient is John Gulland.

John Gulland's involvement with wood burning began in 1974 when he moved to a rural area and built a wood stove for his own home. During the late seventies he worked for a major manufacturer of wood furnaces, responsible for product development, quality control and customer service. He became a consultant in the field in 1981 and served for one year as residential wood energy policy advisor to Energy, Mines and Resources Canada.

While continuing to offer consulting services, he established a highly successful wood stove and fireplace retail store in 1985, which he sold to its manager in 1992. Working under contract to the Canadian Wood Energy Institute (CWEI), he served as principal researcher, writer and project leader in the development of the reference materials and course documents for the acclaimed Wood Energy Technical Training program (WETT).

John has delivered dozens of training seminars and workshops for wood-heat professionals all over North America. He is acknowledged to be one of North America’s foremost experts on chimney installation design and function, especially in tightly constructed houses. He has also led teams of researchers conducting two major combustion venting research projects for Canada Mortgage and Housing Corporation.

From 1990 to 1994, his company provided association management and technical services to Wood Energy Technology Transfer Inc. (WETT Inc.), the national registrar for the WETT program, and to the Association of Registered Wood Energy Technicians of Ontario (ARWETO), its affiliate in Ontario.

In the mid-1990s, he developed a new manual and workshop called Reliable Chimney Venting, which was adopted and published by the U.S. HEARTH Education Foundation. His book, The Hearth in the House as a System is now online. John is deeply involved in initiatives to reduce indoor and outdoor smoke emissions from wood-burning equipment.

WETT is pleased to award John Gulland with our 2023 Award of Excellence.

John accepted his award in person during our AGM on Friday, June 9, 2023 at Horseshoe Valley Resort.

Congratulations to Dave Rayner

Congratulations to Dave Rayner for being recognized recently by the Association of Wood Energy Technicians of Manitoba (AWETM) for his lifetime contributions to the industry.

Dave got his start in the hearth business in 1979. He was well known in the Manitoba market as the owner/operator of “Ye Olde Soot Sweepers”. With time, the business evolved into a retail location called “Ye Olde Hearth Shoppe”.

Dave was one of many volunteers across Canada who helped to establish WETT Inc. and is a founding member of AWETM. Dave was also a long-time instructor for WETT training programs in Manitoba.

From left-to-right: Randy Hoeppner, Past-President of AWET-M; Dave Rayner, and Justin Rayner (Dave’s son and General Manager at Eldur Hearth Products).

WETT is Looking for a Technical Consultant — Ethics

This Request for Proposal (RFP) solicits proposals from qualified individuals in providing consultation services that support WETT Inc. with its member dispute process and subsequent communication with complainants and members.

SCOPE OF WORK TO BE PROVIDED

The following list briefly outlines the scope of work to be provided:

• Serve as a File Coordinator for ethics complaints as outlined in the complaints process;

• Provide technical references in response to members and complainants;

• Attend committee conference calls;

• Provide detailed record of work and invoicing in a timely manner;

• Estimated workload: 150 hours per year.

Click here to download the RFP.

WETT Award of Excellence

John Gulland, WETT 2023 Award of Excellence Recipient

The WETT Award of Excellence recognizes an individual who has made significant contributions to advancing the objectives of WETT Inc.

Our 2023 recipient is John Gulland.

John Gulland's involvement with wood burning began in 1974 when he moved to a rural area and built a wood stove for his own home. During the late seventies he worked for a major manufacturer of wood furnaces, responsible for product development, quality control and customer service. He became a consultant in the field in 1981 and served for one year as residential wood energy policy advisor to Energy, Mines and Resources Canada.

While continuing to offer consulting services, he established a highly successful wood stove and fireplace retail store in 1985, which he sold to its manager in 1992. Working under contract to the Canadian Wood Energy Institute (CWEI), he served as principal researcher, writer and project leader in the development of the reference materials and course documents for the acclaimed Wood Energy Technical Training program (WETT).

John has delivered dozens of training seminars and workshops for wood-heat professionals all over North America. He is acknowledged to be one of North America’s foremost experts on chimney installation design and function, especially in tightly constructed houses. He has also led teams of researchers conducting two major combustion venting research projects for Canada Mortgage and Housing Corporation.

From 1990 to 1994, his company provided association management and technical services to Wood Energy Technology Transfer Inc. (WETT Inc.), the national registrar for the WETT program, and to the Association of Registered Wood Energy Technicians of Ontario (ARWETO), its affiliate in Ontario.

In the mid-1990s, he developed a new manual and workshop called Reliable Chimney Venting, which was adopted and published by the U.S. HEARTH Education Foundation. His book, The Hearth in the House as a System is now online. John is deeply involved in initiatives to reduce indoor and outdoor smoke emissions from wood-burning equipment.

WETT is pleased to award John Gulland with our 2023 Award of Excellence.

John accepted his award in person during our AGM on Friday, June 9, 2023.

Wood-burning Inserts Installed Into Manufactured Fireplaces

By Martin Aubé

Today, in our industry, there is a great debate on the installation of wood-burning inserts into manufactured fireplaces. To clear the air a little: a manufactured fireplace is also known as a prefabricated fireplace (prefab) and/or a zero-clearance fireplace (ZC).

Instead of giving a quick yes or no answer to start, let’s look at several factors in play for this type of installation and what questions we should ask to get to the required information.

What is the insert certified for? What is the fireplace certified for? What chimney is connected to the fireplace? What is the chimney/venting requirement for the insert? What needs to be inspected prior to installation?

Inserts must be certified to ULC S628, which is for installation into masonry fireplaces. There is no current certification standard for wood-burning inserts to be installed into a manufactured fireplace. Manufactured fireplaces are certified to ULC S610. For a ULC S628-certified insert to be installed into a ULC S610-certified manufactured fireplace, the fireplace itself should have been tested for the installation of an insert. What does the manufactured fireplace installation manual state? Many state that the use of uncertified components will void the certification or warranty of the manufactured fireplace.

So, is this ULC S610-certified fireplace certified for use with a ULC S628 insert? The ULC S610 certification allows for either a ULC S604 or ULC S629 chimney system to be used for venting a manufactured fireplace. The wood-burning insert requires a ULC S629 certified chimney system or equivalent, as per the building code. More specifically, the ULC S628-certified insert usually requires a stainless-steel liner as the main exhaust channel inside an appropriate shell/housing. This shell/housing is more commonly a masonry chimney. In some cases, for sizing purposes, a manufactured chimney is acceptable.

Depending on the manufactured chimney used on the fireplace, the chimney could then become a concern for the insert installation. A fireplace with a ULC S629 certified chimney would be able to handle the heat generated by the insert travelling through the stainless-steel liner, whereas a ULC S604 certified chimney does not hold the temperature rating to allow its use to contain a stainless-steel liner connected to a ULC S628 certified insert.

Is the existing chimney a packed insulation or air-cooled system? If air cooled, is the air channel compromised? If an air-cooled chimney is compromised, it would no longer be considered to be “air-cooled” and its certified clearances would no longer apply. Would the chimney have its clearances?” The clearances for the air-cooled chimney are based on having the air channel open.

If an insert were to be installed into a manufactured fireplace — or if there were a code for us to follow for it — what level of inspection would need be done to the original fireplace system? A Basic Visual Inspection would be severely lacking in this regard, as most of the installation is hidden. A Technical or Invasive inspection would not only be necessary to see all the hidden areas, but you would also need to know the following:

Was the manufactured fireplace originally installed correctly?

How old is the original installation? Age by itself is not a hazard. However, years of overheating and/or moisture penetration could create a hazard.

Has the original installation been modified?

Many questions and concerns can arise. The same as any manufactured fireplace inspection, the biggest difference is the “WHY.”

Why would someone want to install an insert into a manufactured fireplace? The most likely cause is to increase efficiency while burning and increase heat output. The worst-case scenario here is the end user may be wanting far more heat than the original manufactured fireplace installation can handle. Also, the grills of a fireplace, if present, may never be blocked or covered. Especially by the insert faceplate/surround. This would also potentially cause an overheat of the original firebox.

Due to the forementioned requirements, in my opinion ULC S628-certified inserts should not be installed into a ULC S610-manufactured fireplace.

History of WETT, Part Two

By: George LeBlanc and John Gulland

In our last History article we recorded as much information as we could find to get us to the beginning of WETT, and now we would like to review the years moving forward with our affiliates and past Presidents.

All of these amazing volunteers worked with Boards and committees to lead the program to where it is today.

In the beginning, the regional Affiliates did most of the field work of promoting and delivering the program.

Here is some background:

WETT Affiliates

ARWETO - Association of Registered Wood Energy Technicians of Ontario

Formed in 1988 by volunteer Board of Governors in association with the government of Ontario. The term ‘Registered’ is significant because it was granted by the government to confer a degree of authority and status as an alternative to the government taking on the training and certification functions itself. ARWETO also hosted a trade show and conference known as the WOOD/GAS Forum for several years in the early 1990s. The ‘Forum’ in 1995 had indoor and outdoor booths for the display and demonstration of products also offered a program of education sessions. Technicians from across the country attended.

The Forum became the gathering for all industry members to meet yearly, to plan the events and training requirements for the following year. ARWETO had some advantages over the other affiliates (perhaps unfairly) because it was in the most populous province and was headquartered in the densely populated ‘Golden Horseshoe’ of Ontario. The Association also had support from the Ontario government, which had been a major funder (along with the Federal government) of the WETT training system.

AWETA - Atlantic Wood Energy Technicians Association (Nova Scotia)

Reported by Mike Kempton in 1995 WETT Ink.

“Formed on September 15th, 1988 by the Wood Heat Steering Committee in Nova Scotia that had been in existence for several years. The first official meeting of AWETA was October 19th, 1988. In 1989 they ran their first WETT course and 10 courses later they had 248 members.

A “Train the trainer” course was held in May 1990, and the pilot for the Volunteer Firefighters course was held with a great response.

Which Course Should I Take?

The new SITE Inspection course is the one all WETT-certified members must complete for their next CE credit.

This course is designed to create more uniformity in inspection activities and reporting. Included in this course are five case studies. Guided by expert instructors, you will be asked to work through scenarios, mimicking an inspection, the process of documenting the inspection through the WETT inspection forms and addressing common challenges. Through actively doing these inspections, you will both gain new knowledge and learn how to apply it.

This course is different from our other courses because it has two parts:

1. the pre-course module

2. the in-class modules

The Pre-course

Once you register for the SITE Inspection course, you will be assigned access to the pre-course.

The pre-course is a one-hour presentation that you watch, followed by a short quiz. You must complete the pre-course before you can attend the in-class course.

You will be sent an email with your course information, which will include the date by which you need to complete the pre-course. It must be completed at the latest one week before your course start date. You will also receive a separate email with the link to access the pre-course.

The In-Class Modules

The in-class portion part of the course is offered both in person and virtually. It takes place over two full days. As with all WETT courses, there will be an exam on the final day of the course. For virtual courses, you will be given access to an online exam.

To view course dates and locations, please check https://members.wettinc.ca/courses/national_calendar.cfm

WETT names winners of the 2022 DuraVent / Security Chimneys Training Bursaries

Wood Energy Technology Transfer is pleased to announce three (3) recipients of the DuraVent / Security Chimneys training bursaries for 2022.

Dustin Block is a woodworker by trade and a bonified wood hound. During the COVID shutdown of 2020/2021, he re-located to Pigeon Lake, Alberta (West of Wetaskiwin); a close-knit community which prides itself on hiring local. Wanting to stay connected with the wood-heat industry and wanting to fulfill a need within the community, he took the WETT core training program and graduated to candidate status in December 2021. His passion for all things wood and wood energy are only growing as more and more people are returning to the principles of local, hand-made products and independent living. Dustin is looking to continue his education towards obtaining full WETT certification as a sweep.

Greg Dumka hails from Dawson City, Yukon. This region is steeply rooted in history as the home of the Klondike Gold Rush back in the late 1800’s; memorialized in the writings of Robert Service, Jack London, Pierre Berton, and many others. Greg started on his path towards WETT certification in 2018. He is a Journeyman carpenter, wood-stove installer, and home inspector. Greg is looking to continue his solid-fuel education with the goal of obtaining full status as a certified sweep.

Fraser Joyes resides in Alberta’s Athabasca region well North of Edmonton. He has been working in construction for over 15 years and achieved full journeyman carpenter status in 2012. Fraser wants to use his skills & experience to benefit residents in his region who heat with wood. Aside from installation & maintenance, he plans to pursue inspection as well. Getting his WETT certification will enable him to help his neighbours in Northern Alberta to ensure their homes are safer and warmer during those long, cold winter days experienced in the North.

We welcome Dustin, Greg, and Fraser to the WETT family!

Congratulations to our 2022 Elizabeth Mason Academic Achievement Award Winner

In memory of Elizabeth Mason, who passed away in 2008, WETT created the Elizabeth Mason Academic Achievement Award.

Elizabeth was a long-standing WETT member committed to advancing the goals of the organization.

WETT is pleased to announce that Terrence McNally — from McBride, BC — is the 2022 award winner.

WETT AGM 2023

This year, WETT's Annual General Meeting will be a hybrid meeting, held in person and virtually via Zoom.

Activity-highlight reports for 2022 will be presented by our provincial affiliates. We will also be presenting our Award of Excellence to our 2023 recipient, John Gulland.

We encourage you to attend, have your voice matter, get informed and ask questions!! Student and Candidate members are welcome to attend, but only current certificate holders may vote.

Date: Friday, June 9, 2023

Location: Horseshoe Resort, 1101 Horseshoe Valley Road, Barrie, ON L4M 4Y8

Time: 4 to 6 p.m. EDT

Zoom meeting details will be provided to those who RSVP to attend virtually.

Click here to RSVP to Attend the AGM Virtually or In Person.